Application

Using this chilly processing line you get the chilly powder as product by processing the whole dry chilly. This is fully automatic line, just feed the chilly in hopper and the whole process is done automatically.

Destoning and Leaf Remover

- This machine consists of two parts

- Vibrator with sieve that removes sand, small stones and seeds.

- Air blower that helps in removing the leaves which are blown out of it using high pressured air.

Stem Cutting

The stem cutting system contains rollers and blades. Using this machine the chilly stem is removed and get saperated from chilly. The chilly is fed into the rollers, the roller contains number of holes at the surface so chilly stem get stuck into these holes. The cutters are place outside the roller, the roller rotates and the cutters keep cutting the stem. Using this process the chilly remains inside the roller and the stem remains outside and get saperated.

Now the chilly is ready to be crushed and is passed to the crusher. We can not grind the chilly in one go because grinding process produces heat and the chemical properties of product gets changed so it is done in two steps, first is crushing and then milling.

Now the chilly is ready to be crushed and is passed to the crusher. We can not grind the chilly in one go because grinding process produces heat and the chemical properties of product gets changed so it is done in two steps, first is crushing and then milling.

Milling

Milling or grinding is done using pinmill.

Pin Mill reduces the average sized material to fine powder and maintains the quality of material. It uses air cooling to maintain the temperature of the final product . There are two rotating disks with pins/knifes, the substance that is to be grinded, is fed into the space between disks and through the grinding motion of the disks the material is converted into powder.

Chilly powder, is then sent for sterilization.

Chilly powder, is then sent for sterilization.

Seiving

A seive is used for sifting the powder to make sure there are no lumps and to get desired mesh size.

Dry Cleaner

After removing the unwa nted conraminants, Dry clening is done to completely clean the chilly. It contains a number of brushes working in sequence, the chilly is passed through these brushes so it gets cleaned completely. And then the chilly is passed to stem cutter.

Crushing

The crusher contains two rotary blades that rotates in opposite directions, the chilly is fed between the blades and cut into small pieces.

Sterilizing

The sterilizer contains layers of conveyor belts, the product is passed through the UV rays to make sure that it is not contaminated with bacteria.

Oil Mixer

Oil is mixed in the chilly powder to give it flavours, The oil mixer mixes the oil with powder.

Vacuum Conveyor

Vacuum Conveyor is used to pull the powder from Seiver, so there is no risk of spreading the chilly powder in the air.

The vacuum conveyor passes the powder to packing machines.

The vacuum conveyor passes the powder to packing machines.

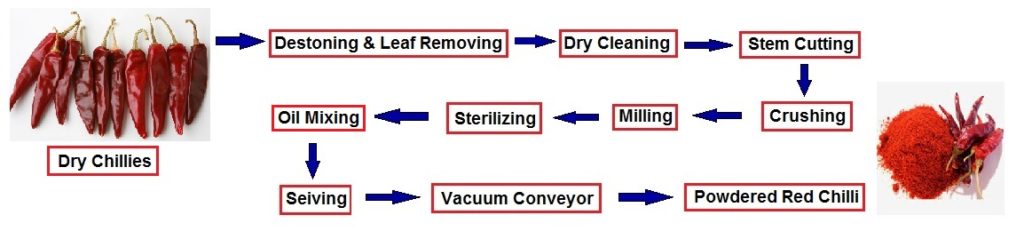

Flowchart for Chilli Line